DOTOP

Provide you with high quality, industrial standard Effective cost-saving conveyor belt solution

Industry experience

Countries and regions

Employees

Plant area

Zhejiang Dotop Industry Co., Ltd. is a rubber conveyor belt production base located in Zhejiang Tiantai County - one of the first batch of AAAA scenic areas of China and known as the “China Rubber Belt Industrial City”. It is close to National Highway 104 and 3 kilometers away from the Tiantai exit of Shangsan Expressway. Dotop is mainly engaged in the design, development, manufacture, sales and service of ordinary V-belt, narrow V-belt, agricultural machinery V-belt, combine V-belt, conveyor belt, flat belt and other products in strict accordance with applicable national standards to provide for our customers a wide product spectrum with high quality. Our products have been sold well in more than 20 provinces and cities in China, and exported to international markets such as South America, Europe, Southeast Asia and the Middle East, winning good brand reputation at home and abroad. Adhering to the tenet of "creating brand with strength, highlighting value with professionalism, and putting quality and reputation in front of quantity and benefit", Dotop is committed to be your best partner to create a win-win future through continual improvement.

A number of invention patents, strive to provide customers with more cost-effective products and services

The construction of general purpose conveyor belts:

• multiply EP carcass (warp polyester + weft polyamide)

• special rubber layer with good fabric adhesion properties (skimmed layer) • high abrasion resistant cover

• special quality of cover on request

| Fabric type | Fabric structure | Fabric specs | Ply thickness (mm/p) | (N/mm) Stiength series | (mm) Cover thickness | (mm) Width | (m) Length | ||||||

| Warp | weft | 2Ply | 3Ply | 4Ply | 5Ply | 6Ply | Upper | Lower | |||||

Polyester (EP) | Polyester (EP) | Polyamine (P) | EP-80 | 0.6 | 160 | 240 | 320 | 400 | 480 | 1.5-12 | 0-4.5 | 400-2500 | ≤300 |

| EP-100 | 0.75 | 200 | 300 | 400 | 500 | 600 | 500-2500 | ||||||

| EP-150 | 1 | 300 | 450 | 600 | 750 | 900 | |||||||

| EP-200 | 1.1 | 400 | 600 | 800 | 1000 | 1200 | |||||||

| EP-250 | 1.25 | 500 | 750 | 1000 | 1250 | 1500 | |||||||

| EP-300 | 1.35 | 600 | 900 | 1200 | 1500 | 1800 | |||||||

| EP-350 | 1.45 | - | 1050 | 1400 | 1750 | 2100 | 800-2500 | ||||||

| EP-400 | 1.55 | - | - | 1600 | 2000 | 2400 | |||||||

| EP-450 | 1.7 | - | - | 2000 | 2500 | 3000 | 1000-2500 | ||||||

Adhesive strength and elongation performance meet the following table

Belt carcass | Adhesive strength | |||||||

Betweenplies | (N/mm) Betweenrubber and carcass | Longitudinal elongation at break | Longitudinal elongation at reterence | |||||

Rubber thickness≤1.5mm | Rubber thickness>1.5 | |||||||

| canvas | ≥4.50 | ≥3.15 | ≥3.50 | 10 | 2 | |||

1. DIN 22012

| Standards | Cover Rubber | ||||

| Tensile Strength | Elongation at Break | Abrasion | |||

| DIN 22102 | Mpa (N/mm) | % | MM3 | ||

| DIN 22102-Z | 15 | 350 | 250 | ||

| DIN 22102-W | 18 | 400 | 90 | ||

| DIN 22102-Y | 20 | 400 | 150 | ||

| DIN 22102-X | 25 | 450 | 120 | ||

Some other letter identification

| Standards | Cover Rubber | ||||

| DIN 22102-E | Anti Static | ||||

| DIN 22102-K | Anti-static and flame retardant | ||||

| DIN 22102-T | Heat resistant | ||||

| DIN 22102-R | Cold resistant | ||||

| DIN 22102-G | Oil resistance | ||||

| DIN 22102-A | For food | ||||

| DIN 22102-C | Chemical resistant | ||||

2. RMA

| Standards | Cover Rubber | ||||

| Tensile Strength | Elongation at Break | Abrasion | |||

| RMA | Mpa (N/mm2) | % | MM3 | ||

| RMA-I | 17 | 400 | 200 | ||

| RMA-II | 14 | 400 | 250 | ||

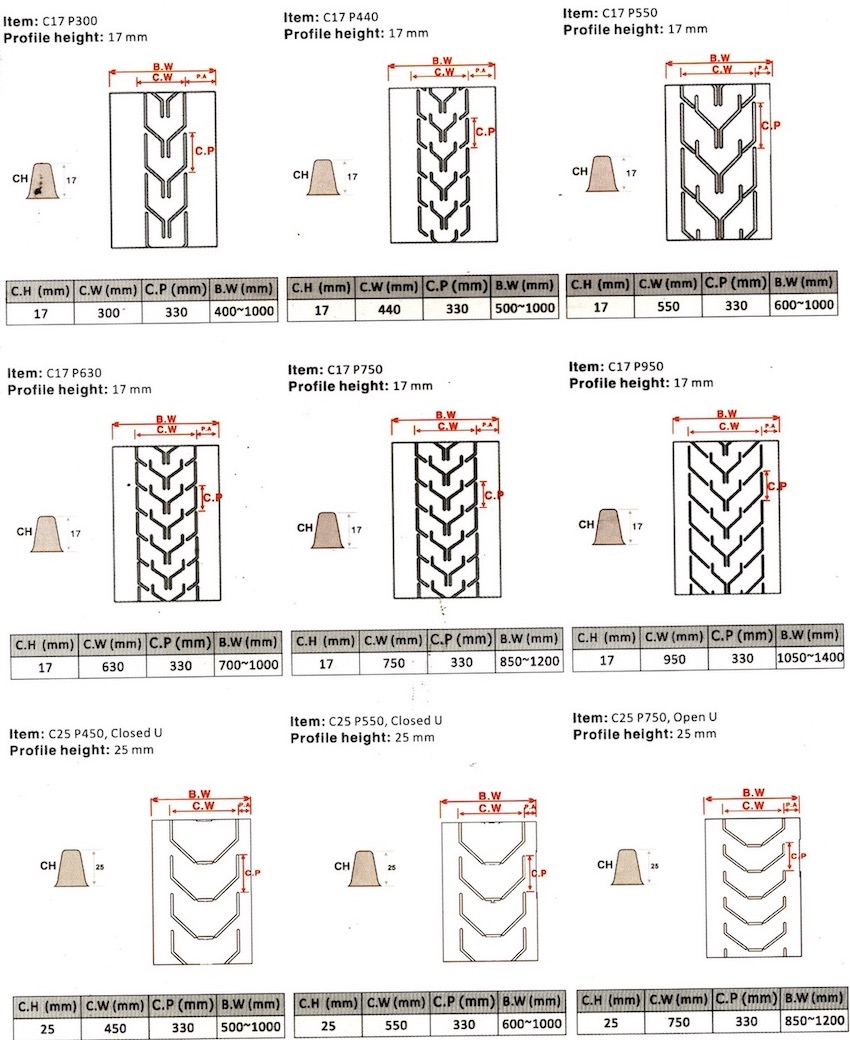

Chevron conveyor belt is composed of belt carcass and pattern. Pattern shape and height(depth) may be different because of different conveyes material and gradient of conveyors.

Application

It can convey powdered,granulates and small lump materials at the gradient of no more than 40;it can also convey packaged materials.

C6/C15/C25/Y32/V6

Chevron Type

| Chevron Type | Pattern | C.H(mm) | C.W(mm) | C.P(mm) | Belt Width | |

| mm | inch | |||||

| C6 | C6-P230 | 6 | 230 | 75 | 300-400 | 12" -16" |

| C6 | 6 | 300-1200 | 100 | 300-1200 | 12" -48" (1215) | |

| V6 | V6 | 6 | 600-1800 | 75 | 600-1800 | 24" -72" |

| C12 | C12-V800 | 12 | 800 | 150 | 800-1200 | 32" -48" (1206) |

| C15 | C15 -V330 | 15 | 330 | 250 | 400-600 | 16" -24" |

| C15-P385 | 15 | 385 | 250 | 500-800 | 20" -32" (800) | |

| C15-V450 | 15 | 450 | 300 | 600-600 | 24" -32" (800) | |

| C15-P500 | 15 | 500 | 340 | 550-750 | 22" -30" (750) | |

| C15-P600 | 15 | 600 | 250 | 750-1000 | 30" -40" | |

| C15-P750 | 15 | 750 | 250 | 900-1200 | 36" -48" (1215) | |

| C25 | C25-P450 | 25 | 450 | 335 | 600-750 | 24" - 30" (750) |

| C25-P550 | 25 | 550 | 250 | 600-800 | 24" -32" | |

| C25-P750 | 25 | 750 | 330 | 900-1200 | 36" -48" (1215) | |

| Y32 | Y32-P450 | 32 | 450 | 255 | 500-800 | 20" -32" (800) |

| Y32-P600 | 32 | 600 | 300 | 800-1000 | 32" -36" | |

| Y32-P800 | 32 | 800 | 333 | 1050-1200 | 36" -48" | |

Mold drawing

The belt core of this product is made of polyester canvas with high modulus, low shrinkage, and extremely high breaking strength, and the covering rubber is made of EPDM or chlorinated butyl rubber with good high-temperature resistance, which is refined by processes including compound molding with high-temperature resistant materials and vulcanization.

After special stain setting treatment, the belt core of this product provides high adhesive strength. Under normal conditions of use below 180 ℃, the product offers small elongation and deformation, and excellent wear performance.

It withstands the high temperature of 250ºC for a short period of time.

It is suitable for use in cement, coking, metallurgy, steel, and other industries.

Model and specifications of the high temperature-resistant conveyor belt

| Fabric model | Strength series(N/mm) | After covering the glue | Width range | Belt length | ||||||

| 2Ply | 3Ply | 4Ply | 5Ply | 6Ply | superior | Down | mm | m | ||

| Polyester(EP) | EP80 | 160 | 240 | 320 | 400 | 480 | 4.5~10 | 0~4.5 | 400~1800 | ≤300 |

| EP100 | 200 | 300 | 400 | 500 | 600 | |||||

| EP150 | 300 | 450 | 600 | 750 | 900 | |||||

| EP200 | 400 | 600 | 800 | 1000 | 1200 | |||||

| EP250 | 500 | 750 | 1000 | 1250 | 1500 | |||||

| EP300 | 600 | 900 | 1200 | 1500 | 1800 | |||||

| EP400 | 800 | 1200 | 1600 | 2000 | 2400 | |||||

| EP500 | 1000 | 1500 | 2000 | 2500 | 3000 | |||||

| Standard | Tensile Strength min. Mpa | Ultimate elongation min. % | Abrasion max. mm | Density g/cm | Basic material | Hardness °Sh | Tenperature range °C |

| T1 | 15 | 400 | 150 | 1.13 | SBR | 60±5 | -20 to +150 |

| T2 | 15 | 400 | 150 | 1.13 | SBR | 60±5 | -20 to +150 |

| T3 | 10 | 400 | 200 | 1.07 | EPDM | 60±5 | -20 to +200 |

Strive to provide customers with more cost-effective products and services

Quality, technology and reputation are the principles that our company always adheres to.